Description

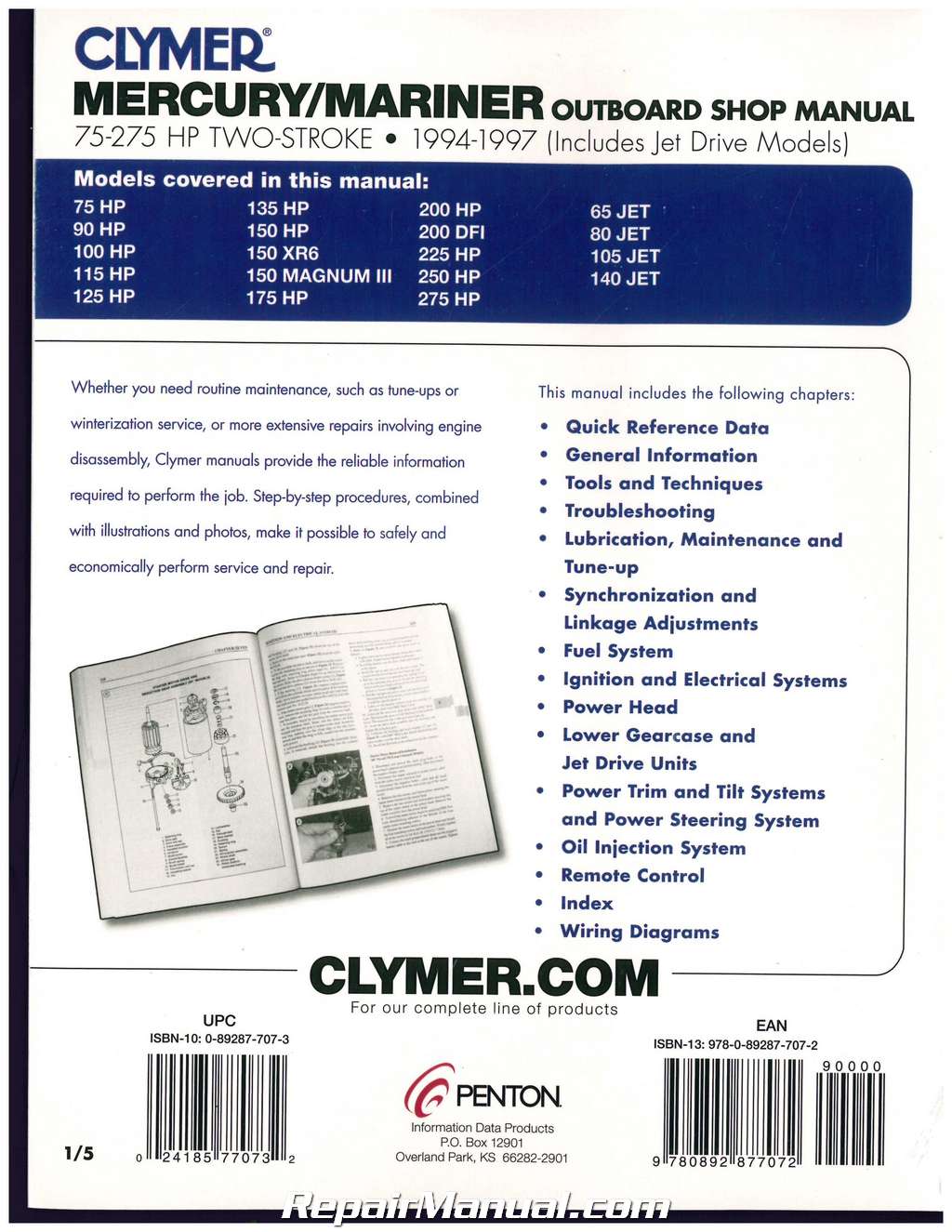

This Clymer Mercury-Mariner Two Stroke Outboard Repair Manual 75-250 hp 1998-2009 provides detailed service information, step-by-step repair instruction and maintenance specifications for 1998-2009 Mercury and Mariner 75-250 hp Outboard boat engines. This is the book you need to properly care and repair your outboard engine. Save a fortune by doing it yourself. Buy a copy to keep on the boat and another to study at home or work.

- Title: 1988 mercury 75hp 2 stroke manual, Author: DonaldMata3033, Name: 1988 mercury 75hp 2 stroke manual, Length: 4 pages, Page: 1, Published: 2017-07-08 Issuu company logo Issuu.

- Mercury 75 HP 2-Stroke Outboard Service Manual. Mercury 75 HP 2-Stroke Outboard service manuals are available for immediate download. This service is available for only $4.95 per download! If you have a dirty old paper copy of this manual or a PDF copy of this manual on your computer and it crashed we can help!

1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009

1956-1989 Manual Covers: 90 through 300 HP models. 1965 to 1989 90-300 hp Inline 6 and V6, 2 stroke models fuel injection and MR Drive: 90 95 100 115 125 135 140 150 150XR2/150 HP 155 HP 175 HP 200 HP 220XRi/200 HP 225 HP 275 HP 300 HP 850XS/90 HP, 4cyl 900/90hp, 6cyl 950/95hp, 6cyl 1000/100hp, 6cyl 1100/100hp, 6cyl 1150/115hp, 6cyl 1250/125hp.

QUICK REFERENCE DATA

CHAPTER ONE, GENERAL INFORMATION

Manual organization, Warnings, cautions and notes, Torque specifications, Engine operation, Fasteners, Lubricants, Gasket sealant, Galvanic corrosion, Propellers

Mercury 75 Hp 2 Stroke Manual

CHAPTER TWO, TOOLS AND TECHNIQUES

Safety first, Basic hand tools, Test equipment, Basic service methods

CHAPTER THREE, TROUBLESHOOTING

2001 Mercury 75hp 2 Stroke Manual

Safety precautions, Operating requirements, Terminology and test equipment, Starting system, Battery charging system, Electrical accessories, Ignition system, Capacitor discharge module (CDM) ignition (65 jet and 75-125 hp, except 105 jet and 115 Optimax) / Alternator driven ignition (1998 and 1999 105 jet and 135-200 hp [except Optimax models]) / Capacitor discharge module (CDM) ignition (200o-on 105 jet and 135-200 hp [except Optimax models]) / Capacitor discharge module (CDM) ignition (225 and 250 hp) / Digital inductive (DI [Optimax models]) / Fuel system, Fuel primer and enrichment systems, EFI fuel system troubleshooting, Optimax 115-225 hp air/fuel system troubleshooting, Engine temperature and overheating, Engine, Starting system troubleshooting, Ignition system troubleshooting, Fuel system troubleshooting, Starter motor current draw specifications, Charging system troubleshooting, Charging system amperage, Battery charging coil (stator) resistance specifications (except belt-driven) system, Ignition system voltage output specifications, Ignition stator resistance specification, Capacitor discharge module (CDM) resistance specifications, Ignition coil resistance specifications, Fuel pump pressure specifications, Engine coolant temperature (ECT) and compressor temperature sensor specifications, Air temperature (IAT) sensor specifications, Cooling system specifications

CHAPTER FOUR, LUBRICATION, MAINTENANCE AND TUNE-UP

Hour meter, Fuels and lubrication, Off-season storage, Anticorrosion maintenance, Engine submersion, Cooling system flushing, Tune-up, Maintenance torque specifications, Maintenance schedule, Spark plug recommendations, Lubricant capacities

CHAPTER FIVE, SYNCHRONIZATION AND LINKAGE ADJUSTMENTS

Safety precautions, Test propeller, General information, 65 jet, 75 hp and 90 hp, 80 jet and 100-125 hp (except 115 Optimax) / 105 jet, 140 jet and 135-200 hp carbureted, 150-200 hp electronic fuel injection (EFI), 115-225 hp Optimax (direct fuel injection), 225 hp carbureted, 225 and 250 hp EFI, General specifications, Synchronization and linkage torque specifications

CHAPTER SIX, FUEL SYSTEM

Fuel pump, Carburetors, Fuel primer valve (65 jet and 75-200 hp [remote control models]) / Thermal air valve (105 jet and 135-200 hp carbureted models) / Fuel enrichment valve (225 hp carbureted models), Accelerator pump circuit (100-125 hp and 80 jet models) / Antisiphon devices, Fuel filters, Fuel tanks, Fuel hose and primer bulb, Electronic fuel injection (EFI) and direction fuel injection (DFI) / Reed valve service, Fuel bleed (recirculation) system, Fuel system torque specifications, Carburetor specifications

CHAPTER SEVEN, ELECTRICAL SYSTEM

Battery, Charging system, Fuses, Starting systems, Ignition systems, Capacitor discharge module (CDM) ignition, Digital inductive ignition (115-225 hp Optimax models) / Electrical system torque specifications, Battery charge percentage, Battery capacity, Battery requirements (minimum), Battery cable requirements

CHAPTER EIGHT, POWER HEAD

Service consideration, Mercury/Mariner model identification, Power head break-in, Service recommendations, Lubricants, sealants and adhesives, Sealing surfaces, Fasteners and torque, Power head removal/installation, Power head disassembly, Power head cleaning and inspection, Power head assembly, Power head torque specifications, Cylinder bore specifications, Piston specifications, Engine characteristic codes

CHAPTER NINE, GEARCASE

Gearcase operation, Service precautions, Corrosion control, Gearcase lubrication, Propeller, Trim tab adjustment, Gear housing, Water pump, Gearcase disassembly/assembly, Gearcase cleaning and inspection, Gearcase pressure testing, Gearcase shimming, Gearcase torque specifications, Gear ratio and tooth counts, Pinion gear locating tool specifications, Gearcase backlash specifications

CHAPTER TEN, JET DRIVE

Jet pump unit maintenance, Jet pump unit repair, Jet drive torque specifications

CHAPTER ELEVEN, TRIM AND TILT SYSTEMS

Power trim and tilt system service, Trim and tilt system torque specifications

2 Stroke Oil

CHAPTER TWELVE, MIDSECTION AND TILLER CONTROL

Mid-section and tiller control torque specifications

CHAPTER THIRTEEN, OIL INJECTION SYSTEM

Variable ratio oil injection (75-125 hp [except 115 hp Optimax and 105 jet], 65 jet and 80 jet models), Variable-ratio oil injection (135-200 hp [except Optimax models], 105 jet and 140 jet models), Variable-ratio oil injectio (225 hp and 250 hp [except Optimax] models) / Variable-ratio electronically controlled oil injection (Optimax models) / Oil injection system torque specifications, Oil injection system specifications

CHAPTER FOURTEEN, REMOTE CONTROL

INDEX

WIRING DIAGRAMS

Using the correct grade of fuel helps to ensure optimum performance, economy and reliability from your engine. It is important to follow the recommendations for your model engine as incorrect fuel can damage your engine or affect performance.

IMPORTANT:

- Using fuel that is below the minimum recommended octane may reduce engine life

- Fuel recommendations are based on engines being set up and tuned to manufacturer's specifications. This includes using the correct propeller to allow engine to achieve recommended maximum RPM under typical load and conditions

- Leaded fuel is not recommended

- Fuel that exceeds 10% ethanol is not recommended

MERCURY & MARINER FUEL RECOMMENDATIONS

- Use a major brand of automotive unleaded petrol (ULP) with a minimum posted octane rating of 91

- These recommendations apply to Mercury and Mariner 2-Stroke, 4-Stroke, Verado and OptiMax models unless specified otherwise (ref to 'Notes & Exceptions' following)

Notes & Exceptions

Verado Models:

- Verado 275/300hp - Premium Unleaded Petrol with a minimum 95 octane recommended for maximum performance

- Verado 350hp - Premium Unleaded Petrol with a minimum 95 Octane Recommended for Maximum performance

- Verado 400R - Premium Unleaded Petrol with a minimum 98 octane

Engines manufactured prior to 1980:

- 2hp to 20hp - Unleaded Petrol (ULP) - minimum 91 Posted Octane

- 30hp & above - Premium Unleaded Petrol (PULP) - minimum 95 Posted Octane

Performance Products will have different requirements, consult your Operation andMaintenance Manual

OIL RATIOS - 2-STROKE MODELS

Pre-Mix Models

Fuel/oil ratio: 50:1 (50 parts fuel to 1 part oil)

Oil requirement: - Certified TC-W3 2-Stroke Outboard Oil

- Mercury or Quicksilver Premium 2-Cycle TC-W3 Outboard Oil

- Mercury or Quicksilver Premium Plus 2-Cycle TC-W3 Outboard Oil

- 2-stroke oil is normally added to the fuel tank when filling with fuel.

- This convenient oil measuring bottle is great for calculating oil required for various volumes of fuel - order part # 67-886696 from your authorised Mercury dealer

Pre-mix is generally used in the following 2-stroke models

2 Stroke Motorcycles

- All 2hp to 30hp models

- All models up to 225hp manufactured prior to 1984

Autoblend Models

Oil requirement: - Certified TC-W3 2-Stroke Outboard Oil

- Mercury or Quicksilver Premium 2-Cycle TC-W3 Outboard Oil

- Mercury or Quicksilver Premium Plus 2-Cycle TC-W3 Outboard Oil

- Autoblend models have an oil reservoir mounted inside the boat that automatically blends oil with the fuel at a constant ratio of 50:1

- 2-stroke oil is added to the reservoir and does not need to be mixed with the fuel (unless required for running-in)

- Autoblend was used on some 35hp to 115hp models manufactured between 1984 and 1988

Oil Injection Models

Oil requirement Fnaf world for mac.

- Conventional 2-stroke models - Certified TC-W3 2-Stroke Outboard Oil

- DFI/OptiMax models - Mercury or Quicksilver OptiMax/DFI 2-Stroke Outboard Oil

- Oil injected models have an oil reservoir mounted under the engine cowl

Mercury/Mariner V6 models have an additional oil reservoir mounted in the boat